Low CTE Reworkable Underfill for Superior Thermal Cycle Performance

Mar 17, 2010

|

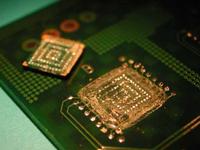

EAST HANOVER, NJ – Zymet has introduced a new silica-filled reworkable board-level underfill encapsulant, X2825, whose coefficient of thermal expansion, CTE, is 26 ppm/°C. The underfill enhances drop and shock test reliability and, compared to higher CTE underfills, provides superior thermal cycle performance. X2825’s lower CTE imparts superior thermal cycle performance. In one trial, thermal cycling of a BGA between -20°C and +85°C, an unfilled version of this product, with a CTE of 60 ppm/°C, resulted in first failure at 500 cycles. X2825 had no failures after 1500 cycles. Addition of silica filler to an otherwise reworkable underfill ordinarily damages reworkability. X2825 is easily reworked, despite the presence of filler. In fact, it is more easily reworked than unfilled reworkable underfills. Rework is accomplished by use of elevated temperature, 170°C to 180°C, to remove the underfill fillet. Then, the BGA is lifted from the board after heating it to above reflow temperature. Underfill residue is easily scraped off, again at 170°C to 180°C. Zymet is a manufacturer of microelectronic and electronic adhesives and encapsulants. Its products include die attach adhesives, substrate adhesives, UV curable glob top and cavity-fill encapsulants, and underfill encapsulants. For more information, contact Zymet, Inc., East Hanover, NJ. Requests for information may also be submitted by Email to info@zymet.com |